Advantages

Quality Assurance System

Supplier Grading System

Level 1: Original Manufacturers, Distributors, Catalog Distributors

Level 2: OEM/ODM/EMS Factories

Level 3: Non-compliant Suppliers

Quality Control &

Data Management

Material System Inbound and Outbound Records

Detailed Photos of Material Inbound

Detailed Photos of Material Outbound

Quality Assurance Letter

Timely Update of Database System

Storage, Packaging &

Transportation Standards

Implement ESD (Electrostatic Discharge) Protection Control

Custom Packaging and Labeling

Establish records for each customer's shipping requirements and choose the fastest, safest, and most economical transportation methods

PMA Return Process

Commit to responding to customer RMA requests within 6 hours and actively provide solutions.

If a material quality issue is confirmed, commit to a full recall of the material and cover all transportation costs.

Quality Assurance Process

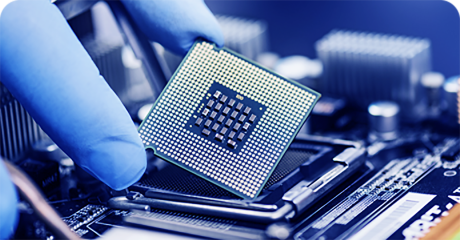

Visual Inspection

Brand, Model, Quantity, Production Date, and ROHS Compliance Inspection

Outer Packaging Inspection, checking if the packaging is intact/completed and if the packaging materials meet the relevant MSL (Moisture Sensitivity Level) standards

Silkscreen Marking Inspection, Consistency Check, and Verification Against Original Manufacturer Specifications

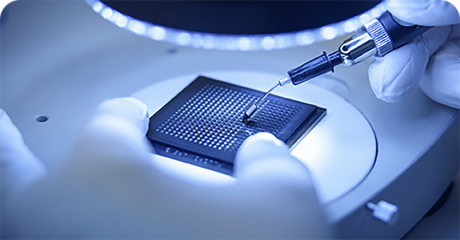

Quality Test

Solderability Test

X-Ray Consistency Test

XRF/EDX/EDS Testing" (X-Ray Fluorescence, Energy-Dispersive X-ray Spectroscopy)

Functionality Test

Training System

All employees are required to participate in training courses, not limited to the quality management team.

The Yicheng training program helps us understand the latest trends in the manufacturing industry, best practices, and new counterfeiting techniques.

Quality manager has an average of 8 years of experience in their field.